MP Dry Cabinet Standard ST Series

The MP DRY CABINET ST series have an outstanding performance for drying moisture sensitive components and PCB’s.

Self-constructed dynamic drying unit MPDRY5 of the MP DRY CABINET series reaches very reliable low humidity values of ≤0.5% RH and automatically regenerates if necessary.

As a result of an insulated double metal sandwich construction a precise temperature of 70°C can be reached with very low power consumption. A radial fan and heater supports the drying process and an appropriate temperature and moisture level in the cabinet.

These low humidity levels are achieved by the use of ROTRONIC sensors.

Why MP Dry cabinets?

MP Dry Cabinets

Dry cabinets are an alternative to moisture barrier bags that can greatly reduce the risk of operator handling errors.

The metal cabinets feature tightly sealed doors and multiple shelves for storing trays and reels for extended periods of time.

Moisture Classification

Two standards help electronics manufacturers tackle the challenges of moisture sensitivity: IPC/JEDEC J-STD-020B and IPC/JEDEC J-STD-033C. The joint industry standards were developed by IPC (Bannockburn, IL) and JEDEC Solid State Technology Association (Arlington, VA).

Moisture-sensitive devices (MSDs)

Moisture-sensitive devices (MSDs) are electronic compo- nents encapsulated with plastic compounds and other organic materials. Moisture from atmospheric humidity enters permeable packaging materials by diffusion and collects at the interfaces of dissimilar material.

IMSD2000 Smart MSD Cabinet

The Smart MSD helps prevent your components from micro-cracking during reflow through proper management of humidity control. Digital display shows temperature and relative humidity percentage within the Smart MSD. System manages components in accordance with the J-STD-033B standard. MSD levels managed are 2, 2a 3, 4, 5, 5a.

Store a variety of parts with standard InoAuto Smart Storage locations, up to 640 SMT reels.

• MP Dry Cabinet technology maintains low humidity (<5% RH) for safe storage of MSL Components.

• Monitor humidity levels in real-time.

• Automatically track the floor life of components with InoAuto MSD Tracking software.

The Smart MSD rack uses a desiccant dryer system to remove moisture from the air. This dry air is then circulated throughout the system to maintain less than 5% relative humidity. When a customer needs to place a package into the Smart MSD Cart, they scan the package information into the system, and place it into any location, exactly like our traditional smart racks. The Smart MSD Cart detects when the doors are opened and closed, and any transactions are recorded in our InoAuto software for complete traceability.

When customers need to retrieve parts, they can browse the inventory or upload a picklist. Any smart locations containing required packages will illuminate allowing the customer to quickly and efficiently locate their parts.

The Smart MSD rack detects when customers open and close a door, automatically records package removal, and can return to under 5% RH in under 5 minutes instead of 30 to 90 minutes for a standard dry box.

A relative humidity sensor monitors the system to ensure proper performance.

The InoAuto MSD tracking software can be fed with transaction data and humidity data to properly track the life of MSD components, based on their sensitivity level, to give customers powerful auditing and traceability features. The Smart MSD Cart can be used in conjunction with our other Smart Storage Solutions.

Additionally, Inovaxe’s flexible API can be used to communicate with customer software, such as MRP, ERP, and MES.

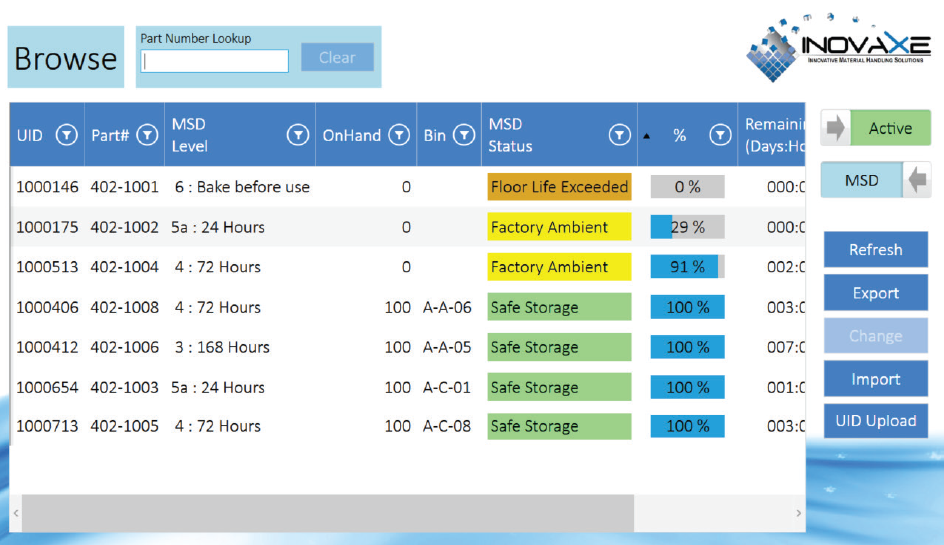

Displays condition and state of each package including assigned MSD level, MSD status, percentage of Floor Life remaining, as well as quantity and location of parts.

MSD tracking software triggers when a package is moved from “safe storage” to “factory ambient” condition and starts progressing remaining Floor Life.

MSD status flags show parts in Factory Ambient, Safe Storage, Drying, Baking, or Exceeded Allowed Floor Life conditions.

The tracking software monitors the regeneration (drying) of component Floor Life when moved from “factory ambient” condition to “safe storage”

On-screen alarm indicates when a user defined percentage of Floor Life is reached.

MP Dry Cabinet Standard

Dry Cabinet I ST

- External dimensions (whd) : 700x1070x690 mm

- Internal dimensions (whd) : 640x800x520 mm

- Precision sensor, accuracy +/- 0.8% RH, +/- 0.1K

- Effective capacity: 260 l

- Full graphical touch screen display

- Stainless steel ESD safe design, quipped with 4 pcs of ESD wheels

- Number of shelves: 3 pcs, made from stainless steel

- Acoustic alarm for open door, time defined by user

- Internal memory and USB connector for report recording, time period defined by user

- Recording of every door opening and closing including actual process parameters

- Password protection for process parameters setup

- Acoustic alarm for drying function error

Dry Cabinet II ST

- External dimensions (whd) : 700x1920x690 mm

- Internal dimensions (whd) : 640x1650x520 mm

- Precision sensor, accuracy +/- 0.8% RH, +/- 0.1K

- Effective capacity: 550 l

- Full graphical touch screen display

- Stainless steel ESD safe design, quipped with 4 pcs of ESD wheels

- Number of shelves: 5 pcs, made from stainless steel

- Acoustic alarm for open door, time defined by user

- Internal memory and USB connector for report recording time period defined by user

- Recording of every door opening including duration

- Password protection for process parameter setup

- Alarm for drying function error

Dry Cabinet IV ST

- Dry Unit: 2x MPDRY5

- External dimensions (whd) : 1410x1920x680 mm

- Internal dimensions (whd) : 1280x1520x520 mm

- Precision sensor, accuracy +/- 0.8% RH, +/- 0.1K

- Effective capacity: 1010 l

- Full graphical touch screen display

- Stainless steel ESD safe design, quipped with 4 pcs of ESD wheels

- Number of shelves: 10 pcs, made from stainless steel

- Acoustic alarm for open door, time defined by user

- Internal memory and USB connector for report recording, time period defined by user

- Recording of every door opening including duration

- Password protection for process parameter setup

- Alarm for drying function error