Solutions for SMT Material Handling and Accuracy Issues

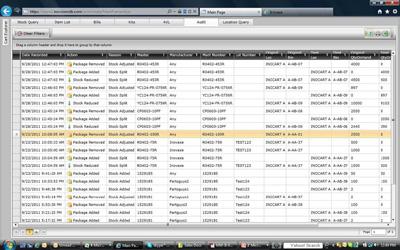

INOVIEW

Single Package Single Location Inventory Solutions

- Upload spreadsheet of BOM/pick list to pull/return parts

- Package Quick Add - Inventory upload feature using barcode scanner

- Manage your stock to WIP process within manual and automated production lines

- Regulatory Compliance Management – RoHS

- Transactions – Add/deplete inventory, inventory movement

- Manufacturer component lot display for In stock components

- Advanced search functionality

- Microsoft Windows compatible

Features

- Quickly Identifies Part Locations

- Promotes Utilization of Broken Packages First

- Results in Substantially Enhanced Inventory Accuracy

- Reduce Line Down Due to Surprise Shortages

- Powerful Part Search Capability

- Provides Lot Traceability

- Min Max Capability

- Minimizes wrong parts being Loaded into Machines

- Reduction in SMT setup/reload time

- Improved material flow and process

- Real-time reports to manage your business

- Minimizes Work in Process (WIP)

- Manages multi-warehouse, multi-WIP inventory

- Kit management capability

Available Options

- Component Master - Master/manufacturer level part numbering system

- BOM/AVL management

- Kit management

- Finished Goods Disposition – Export and edit capability

- Min/Max management and export

- Transaction tracking, item audit, history, transaction, and lot tracability reports