InoAuto Smart MSD Cart

The Smart MSD helps prevent your components from micro-cracking during reflow through proper management of humidity control. Digital display shows temperature and relative humidity percentage within the Smart MSD. System manages components in accordance with the J-STD-033B standard. MSD levels managed are 2, 2a 3, 4, 5, 5a.

Store a variety of parts with standard InoAuto Smart Storage locations, up to 640 SMT reels.

• MP Dry Cabinet technology maintains low humidity (<5% RH) for safe storage of MSL Components.

• Monitor humidity levels in real-time.

• Automatically track the floor life of components with InoAuto MSD Tracking software.

The Smart MSD rack uses a desiccant dryer system to remove moisture from the air. This dry air is then circulated throughout the system to maintain less than 5% relative humidity. When a customer needs to place a package into the Smart MSD Cart, they scan the package information into the system, and place it into any location, exactly like our traditional smart racks. The Smart MSD Cart detects when the doors are opened and closed, and any transactions are recorded in our InoAuto software for complete traceability.

When customers need to retrieve parts, they can browse the inventory or upload a picklist. Any smart locations containing required packages will illuminate allowing the customer to quickly and efficiently locate their parts.

The Smart MSD rack detects when customers open and close a door, automatically records package removal, and can return to under 5% RH in under 5 minutes instead of 30 to 90 minutes for a standard dry box.

A relative humidity sensor monitors the system to ensure proper performance.

The InoAuto MSD tracking software can be fed with transaction data and humidity data to properly track the life of MSD components, based on their sensitivity level, to give customers powerful auditing and traceability features. The Smart MSD Cart can be used in conjunction with our other Smart Storage Solutions.

Additionally, Inovaxe’s flexible API can be used to communicate with customer software, such as MRP, ERP, and MES.

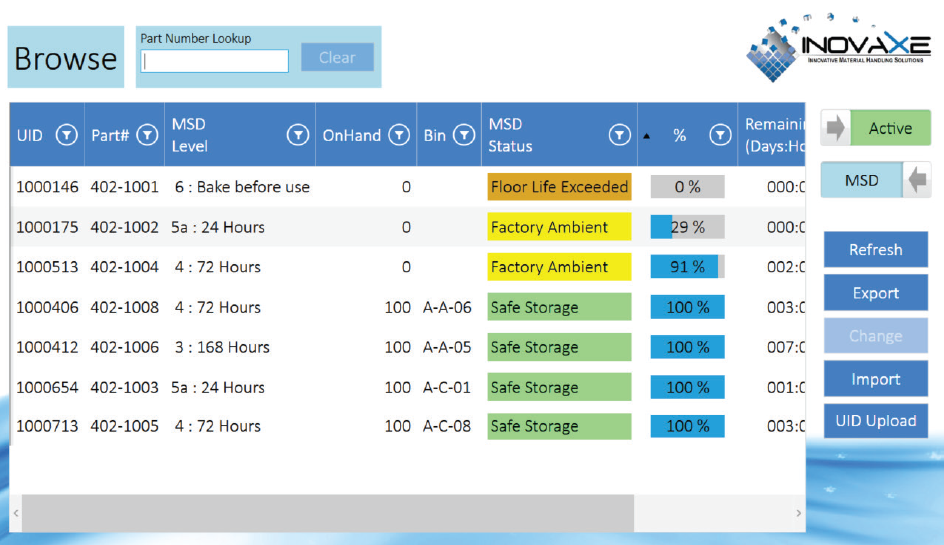

Displays condition and state of each package including assigned MSD level, MSD status, percentage of Floor Life remaining, as well as quantity and location of parts.

MSD tracking software triggers when a package is moved from “safe storage” to “factory ambient” condition and starts progressing remaining Floor Life.

MSD status flags show parts in Factory Ambient, Safe Storage, Drying, Baking, or Exceeded Allowed Floor Life conditions.

The tracking software monitors the regeneration (drying) of component Floor Life when moved from “factory ambient” condition to “safe storage”

On-screen alarm indicates when a user defined percentage of Floor Life is reached.

InoAuto Smart Stencil Rack

The Smart Stencil Rack is 29” long by 23.45” wide, and 68” tall. It can hold two rows of stencils. Each row can be configured for 12 smart locations for standard-width stencils, or 32 smart locations for space-saver stencils. The product is designed to RoHS specifications and minimizes space and material usage in its construction.

Each smart location has a sensor to detect when stencils are placed or removed, as well as an LED to indicate where stencils are located, and provide feedback when adding reels. To add a stencil to the rack, the customer either scans or enters the stencil part number and adds the stencil to any available location. The Smart Stencil Rack detects where the stencil was placed, and stores this for future retrieval.

Each stencil can be stored or retrieved in under 10 seconds.

When a stencil is required for a job, the customer can browse for the correct stencil number(s) or import a pick list containing the required stencil part number(s). The stencil requirement can also be sent automatically through Inovaxe’s flexible API. The Smart Stencil Rack will illuminate the location(s) of the required stencil(s) and the customer can simply remove the stencil(s) at the indicated location(s). If an incorrect stencil is removed, the picking process is shut down and the Smart Stencil Rack indicates that an unauthorized pick has occurred. It also allows manufacturers reduce the need for paper pick sheets, and paper reports.

The InoAuto Smart Stencil Rack has been designed to increase the speed of storing and retrieving solder stencils. Each stencil can be stored or retrieved in under 10 seconds. Operators do not have to spend time searching for the correct location to put their stencil away, as they simply place the stencil into any available slot. When retrieving stencils, we quickly light up the correct location, so the operator does not have to spend time searching for and verifying the location to pull from. The Smart Stencil Rack is also designed to decrease the space required to store stencils. Each slot is designed to perfectly fit the standard stencil sizes, eliminating any wasted space.

The InoAuto Smart Stencil Rack is compatible with Inovaxe’s InoAuto locator software, as well as with Inovaxe’s kit and stock management software, InoView. The Smart Stencil Rack can be used in conjunction with our other Smart Storage Solutions. Additionally, Inovaxe’s flexible API can be used to communicate with customer software, such as MRP, ERP, and MES.